XINYUAN Customized

We provide professional special customization services to ensure that each ziplock bag fits your product and brand perfectly.

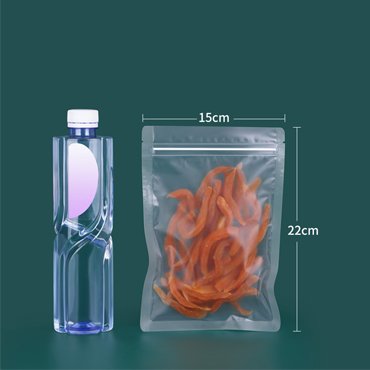

- Specific Sizes: No matter how big or small your product is, we can create a ziplock bag in a specific size according to your requirements, ensuring a perfect fit.

- Printing logos and patterns: Through high-quality printing technology, we can print your brand logo, logo and unique design on ziplock bags to enhance your brand image.

- Special Designs: If you have unique design needs, our design team will work with you to create a ziplock bag design that meets your requirements and makes your product stand out.

- Custom Colors: We offer a variety of color options to ensure the ziplock bags match your brand tone and enhance the visual impact.

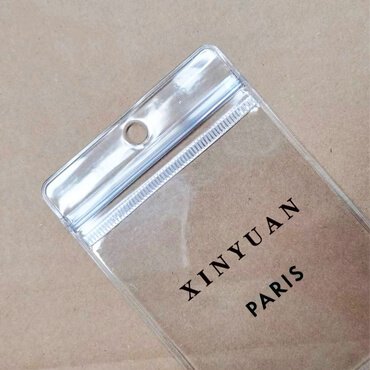

- Additional features: Based on your needs, we can add additional features such as zipper closures, air-tight performance, clear windows, etc. to suit specific uses.

XINYUAN Ziplock Bags

Welcome to XIN YUAN Paper and Plastic Products Packaging Co., Ltd., your first choice for professional ziplock bag manufacturers! We are leaders in the industry, committed to providing high-quality, innovative ziplock bag solutions. At XIN YUAN, we understand the importance of packaging for product preservation, display and transportation, so we carefully design and produce various types of ziplock bags to meet the needs of different industries.

Why choose XINYUAN:

Excellent professional team: Our professional production team has many years of experience and is proficient in the design, manufacturing and printing technology of ziplock bags, ensuring that every detail meets the highest standards.

Wide range of products: From transparent bags to printed bags, we provide a diverse range of products suitable for many industries such as food, electronics, daily necessities, etc.

Innovative process: We adopt the most advanced production process and pay attention to quality and details to ensure that each ziplock bag has excellent moisture-proof performance, durability and visual effect.

Environmental protection commitment: We actively advocate the concept of environmental protection, use recyclable materials and biodegradable materials, and contribute to the cause of environmental protection.

At XINYUAN, we are committed to providing excellent packaging solutions for your products, making your products more quality and competitive. Choose XINYUAN, choose professionalism, choose quality!

Biological sample bags have leak-proof design, tamper-proof seal and biohazard label, and some have temperature control function to ensure sample safety. They are mainly used for sample transportation in medical testing, scientific research, public health and environmental monitoring.

UV protective bags are made of UV-resistant materials, durable and available in a variety of specifications, some with sealing functions. They are mainly used to protect photosensitive chemicals, medicines, electronic equipment and food from UV damage, extend their service life and maintain quality.

Special-shaped bags have customized designs, multiple material choices and rich printing and decoration options. They are mainly used for brand promotion, product packaging and gift packaging to enhance product appeal and recognition.

PVC zipper bags are durable, waterproof and dustproof, with transparent design for easy viewing of contents, zipper closure for security, and available in a variety of sizes. Mainly used for stationery storage, travel supplies organization, food storage and electronic product protection.

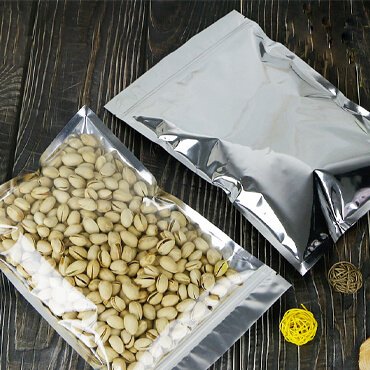

Food zipper bags, also known as fresh-keeping bags, are suitable for storing a variety of items. The zipper seal ensures safety and is not easy to leak. There are many materials and sizes to choose from.

Holographic zipper bags have a rainbow-like holographic reflective effect, zipper closure to ensure the safety of items, durable waterproof material, and come in a variety of sizes. Mainly used for fashionable packaging of cosmetics, jewelry, small gifts, and storage of stationery, travel goods and food

Zipper barrier bags have high barrier properties, are moisture-proof, oxygen-proof, and UV-proof, and are made of durable materials. Zipper closures facilitate multiple openings and closings. They are mainly used for the safe storage and protection of food, medicines, and electronic products.

OPP bags are highly transparent, durable and well sealed, and are available in a variety of sizes. They are mainly used for packaging and protection of stationery, toys, clothing, food, gifts and documents.

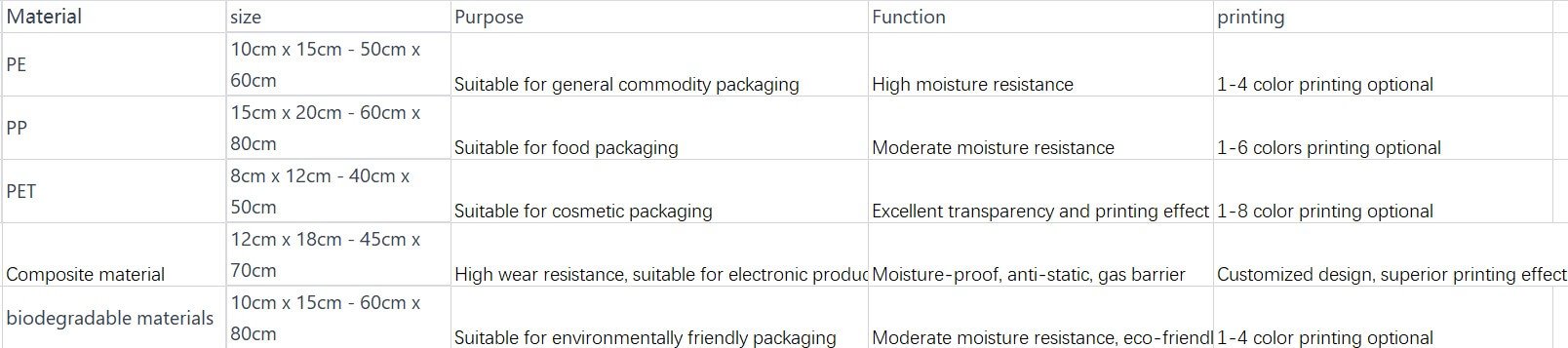

Ziplock Bag Product Material

Capabilities and Product Functions

Product Feature Box

Superior moisture-proof performance ensures that products stay fresh for a long time.

Convenient sealing design, easy to open and reseal, providing a convenient use experience.

Supports a variety of customization options, including printing company logo to highlight unique brand image.

Provide different material options to meet various product packaging needs, and environmentally friendly materials can be selected

Online Service

Online consultation: Our professional team is ready to provide you with online consultation services. If you have any questions about product specifications, customization needs, pricing, etc., you can contact us through live chat, email or online form on the website.

Product customization: We provide flexible product customization services to meet customers’ personalized needs. Through the online platform, you can submit your customization requirements and our team will contact you as soon as possible to discuss and confirm the customization details.

Quotation Inquiry: If you are interested in our products or need to obtain a quotation, you can fill in the quotation inquiry form online and we will respond promptly and provide you with detailed product quotation information.

Online ordering: We provide convenient online ordering service. Customers can select the desired product specifications on the website, fill in the order information, and complete payment through the secure online payment system. We will process your order and arrange shipping as soon as possible.

After-sales service: During the use of our products, if you encounter any problems or have any feedback, our after-sales service team will respond promptly. You can submit questions through online channels or call our customer service hotline for assistance.

Technical support: For technical issues, we provide professional technical support services. Customers can ask questions to our technical team through online consultation, email, etc., and obtain detailed answers and suggestions.

Company Experience and History

Years of establishment: We were established in 2005 and have many years of successful operating experience in the packaging bag industry. During this time, we have continued to grow and accumulate rich industry experience.

Industry status: XINYUAN has become one of the leading companies in the packaging bag industry. Through unremitting efforts and persistence in product quality, we have won the trust of our customers and established a good market reputation.

Product range: We focus on producing various types of packaging bags, covering multiple application fields such as food packaging, pharmaceutical packaging, and electronic product packaging. Whether it is standard specifications or custom designs, we can provide comprehensive solutions.

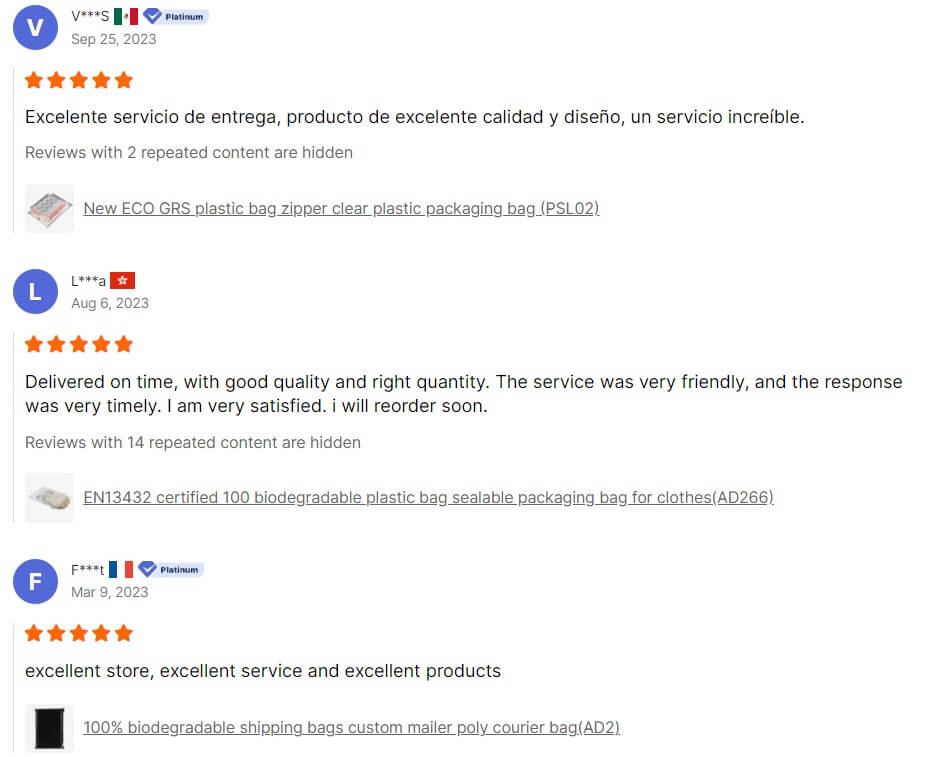

Customer Group: Our customer base is extensive, including the food industry, medical industry, electronics industry, daily chemical industry, etc. We have established long-term and stable cooperative relationships with many enterprises. Our products not only meet the needs of domestic customers, but are also exported to international markets and have won the favor of international customers.

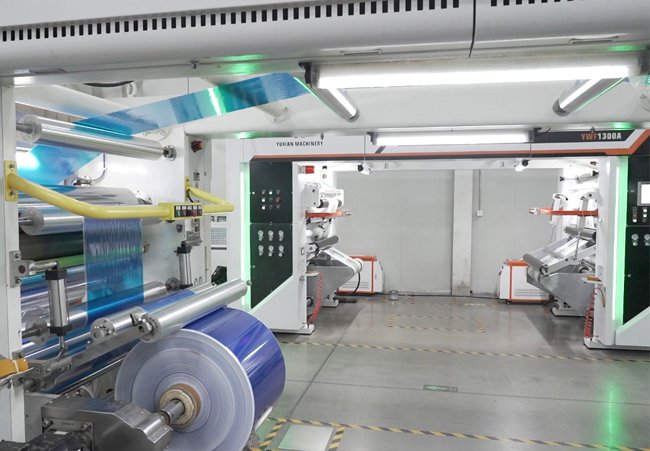

Innovation and Development: We have always been committed to technological innovation and product development. By introducing advanced production equipment and technology, we continuously improve product quality and production efficiency to adapt to the changing market and increasing customer needs.

Quality Management

Strict control of raw materials: We purchase high-quality raw materials from reliable suppliers and conduct strict raw material inspections. Only raw materials that meet quality standards are used in production.

Production process monitoring: We have implemented strict production process monitoring, including printing, cutting, bag making and other links. Each link is supervised by professionals to ensure that each ziplock bag meets design and quality requirements.

Finished product inspection: At the finished product stage, we conduct comprehensive inspection, including dimensional measurement, printing quality, sealing performance and other aspects. Only ziplock bags that pass strict inspection will be recognized as qualified products.

Comply with industry standards: Our ziplock bag products strictly follow relevant international and industry standards. Whether it is food packaging, pharmaceutical packaging or other application fields, we ensure that our products comply with regulations and standards and provide customers with safe and reliable products.

Continuous improvement: We focus on continuous improvement and constantly optimize the quality management process. By collecting customer feedback and internal reviews, we seek opportunities to improve product quality and service levels to meet our customers’ changing needs.

Material selection: We select high-quality raw materials, including polyethylene, polypropylene, PET, aluminum foil, etc. The choice of materials directly affects the performance and quality of the bag.

Design and customization: We work closely with our customers to understand their needs and provide professional advice. According to the customer’s requirements, we design and customize the ziplock bags to ensure that they meet the product’s characteristics and packaging needs.

Printing technology: We use advanced printing technology, including flexographic printing, offset printing, screen printing, etc., to ensure clear and lasting printing effects. Customers can choose to print personalized patterns, logos and text to achieve brand promotion.

Cutting and bag making: We introduce advanced cutting and bag making equipment to ensure that each ziplock bag has a consistent size and shape. Precise cutting and bag making processes are important steps to ensure product quality.

Special processing: According to customer needs, we can perform special processing, such as adding zipper seals, making transparent windows, implementing air seals, etc. These processes can provide additional functionality and features.

Quality Control: We implement strict quality control procedures and closely monitor multiple links from raw material inspection to printing and bag making. Only ziplock bags that pass strict quality inspection will be delivered to customers.

Packaging and Delivery: After completing production, we carefully package the ziplock bags to ensure they are not damaged during transportation. We work with reliable logistics to deliver products to customers on time.

Our ziplock bag products strictly follow relevant international and industry standards. Whether it is food packaging, pharmaceutical packaging, electronic product packaging or other application fields, we ensure that our products comply with the regulations and standards of relevant industries and provide customers with safe and reliable packaging bag solutions.

We have implemented strict quality control processes, including:

Raw material inspection: All raw materials entering the factory are strictly inspected to ensure that they meet quality requirements.

Production process monitoring: Strict monitoring is implemented in production links such as printing, cutting and bag making to ensure that every link reaches high quality standards.

Finished product inspection: Conduct a comprehensive inspection of the finished product, including size, printing quality, sealing performance and other aspects to ensure that the product fully meets customer expectations.

Reference case

The customer wanted to highlight his logo: JZ, and wanted to print the bag in full pink. We helped the customer solve this problem.

This customer required a highly customized ziplock bag for packaging their small electronics such as headphones and chargers. They wanted the bags to not only provide superior moisture-proof and anti-static properties, but also have the company’s brand logo and product specifications printed on the packaging.We provide our customers with a composite ziplock bag that combines polyethylene and aluminum foil to ensure that the product is not affected by moisture and static electricity during the packaging process.

The customer wanted a custom medical biospecimen transport bag that needed to be used to store specimens, with a separate bag on the back for storing documents, and a clearly legible logo on the front and an option for easy recording.

- Specification Reference

FAQ: Wholesale and Customization of Ziplock Bags

Of course. We provide personalized customization services, including printing company logos, patterns or text. Please provide your design or logo files and our design team will work with you to ensure the printing results meet your expectations.

We provide ziplock bags in a variety of materials, including polyethylene, polypropylene, PET, aluminum foil, etc. Each material has different properties and is suitable for different packaging needs. We can provide professional advice based on your product and application.

Yes, we offer eco-friendly options, including ziplock bags made from recyclable or biodegradable materials. Please tell us your environmental protection requirements and we will provide you with corresponding solutions.

Yes, we can provide a limited number of free samples for your quality testing. Please contact our customer service team with your detailed needs and we will try our best to meet your requirements.

Of course. We have a professional design team that can provide you with design suggestions and technical support. Please tell us your ideas and needs and we will work with you to ensure the best ziplock bag design.

The production lead time depends on your order size, customization requirements and current production schedule. Generally speaking, the production cycle for standard orders is 10-15 working days after the design is confirmed. Please confirm delivery time with our sales team before placing order.