Non Woven Bags Factory

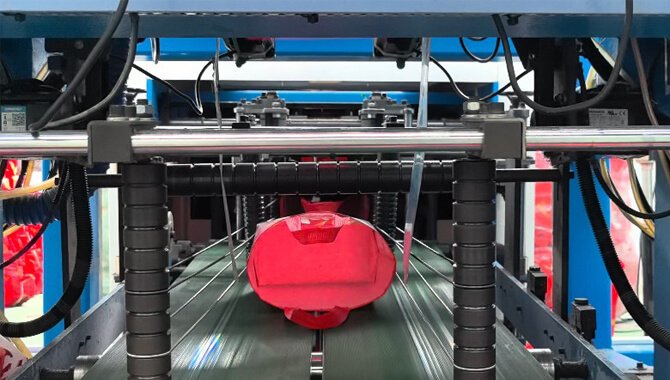

- Fully automatic equipment, one-time molding

- Five-layer composite bag is waterproof, load-bearing, and tear-resistant

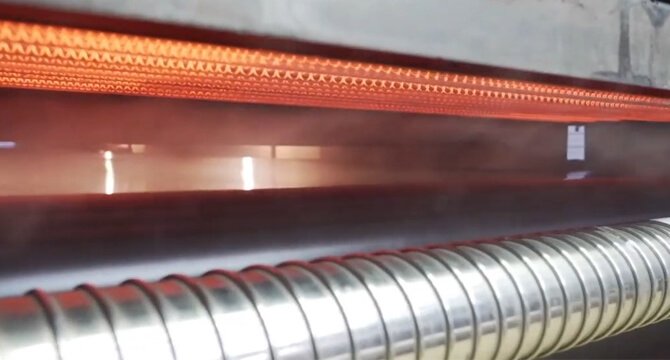

- Print first, then compound and then make the finished product, using a double-layer ten-color printing machine

- Can be customized in large quantities and shipped quickly

- High-quality five-layer composite non-woven bag uses high-tech flow rock composite technology to eliminate sol composite.

- Double-layer ten-color printing machine, screen printing technology

- Single-layer hand-sewn non-woven bags are also available, but screen printing is required

XINYUAN Non Woven Bags

Non-woven bags are highly favored in today’s market due to their environmental protection, durability and versatility, becoming the first choice in the retail industry, promotions and gift markets. This type of bag is not only popular because of its lightness and strong load-bearing capacity, but also because of its recyclable and degradable characteristics, which greatly reduces the impact on the environment. Non-woven bags have a wide range of applications, from everyday shopping bags to professional promotional and custom gift bags, and their elegant appearance and practicality make them ideal for enhancing your brand image.

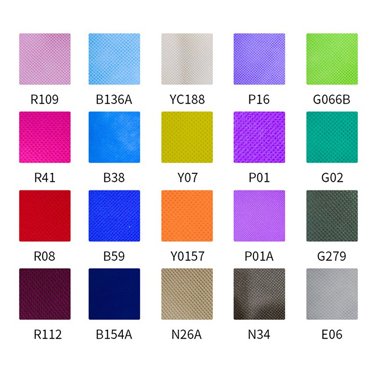

Our company is committed to providing high-quality non-woven bag solutions, combining advanced production technology and strict quality control systems to ensure that each product can meet customers’ high standard requirements. Our non-woven bag products not only come with diverse design and functional options such as multiple sizes, color options and custom printing, but also offer fast delivery services to meet our customers’ pressing market needs. Through continuous technological innovation and research on environmentally friendly materials, our company aims to promote sustainable development strategies and help customers achieve business goals while also contributing to environmental protection.

In this era where environmental protection and sustainability are core values, choosing our non-woven bags is not only a choice of quality and practicality, but also an investment in environmental responsibility and brand image. Our professional team is committed to working closely with customers to provide personalized solutions to ensure that each product can accurately convey the customer’s brand message while enhancing the consumer experience.

Some Application Areas

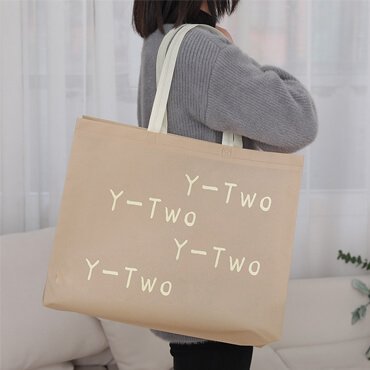

We mainly promote five-layer composite non-woven bags, which are printed using advanced printing machines. We also support mass customization of single-layer hand-sewn bags using screen printing.

Supermarkets and Grocery Stores: Non-woven bags are an ideal shopping bag to replace single-use plastic bags and help reduce plastic waste.

Apparel and Footwear Retail: High-quality and customizable non-woven bags are often used as a tool to promote branding and increase customer satisfaction.

Corporate promotion: Companies often promote their brands by printing company logos and slogans on non-woven bags.

Exhibitions and Events: Customized non-woven bags are widely used as promotional materials in various commercial exhibitions and events.

Takeout and fast food: Non-woven bags are used for takeout services due to their strong load-bearing capacity and good ability to maintain food temperature.

Food packaging: Specific types of non-woven bags can also be used to directly package food, such as bread, fruits, etc.

Environmental promotion: As a reusable and recyclable packaging option, non-woven bags are often used in environmental promotion campaigns to encourage a more environmentally friendly lifestyle.

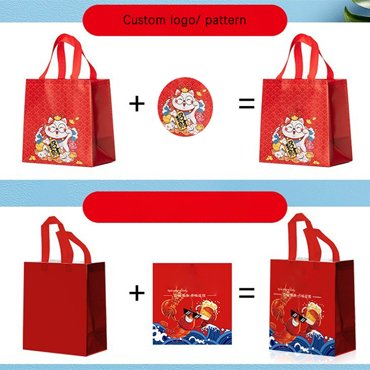

Support Customization

Quality Control System

Product Feature Box

Material Properties

Lightweight: The light weight of non-woven fabric makes the final bag easy to carry and very user-friendly.

Durability: Although lightweight, non-woven fabrics have good durability and strength and can withstand heavy objects without tearing easily, making them suitable for repeated use.

Recyclability: Non-woven fabrics are made of materials such as polypropylene (PP), which can be recycled and reused to reduce resource waste.

Partially biodegradable: Some non-woven bags use biodegradable materials, which have less impact on the environment.

Water resistance and air permeability: Non-woven fabrics have good water resistance while maintaining a certain degree of air permeability, which is beneficial to keeping the items in the package dry and ventilated.

Production Capacity

With strong production capabilities and efficient operating models, our company is able to meet the needs of customers of all sizes:

Annual output: We have the ability to produce millions of non-woven bags to ensure large-scale supply.

Fast delivery: Efficient production processes and response mechanisms ensure that orders can be completed quickly and urgent needs can be met.

Large-volume orders: Advanced production lines and strict quality control can handle large-scale orders smoothly and ensure quality and quantity.

Technology and Human Resources: Invest in the latest technology and employee training to improve production efficiency and product quality.

Customer Service: A professional team provides full service, from order processing to shipment, ensuring smooth communication and high satisfaction.

Environmental Protection and Sustainability

material selection

We prioritize environmentally friendly and sustainable raw materials, such as using certified recyclable non-woven materials and environmentally friendly dyes. These materials not only reduce the consumption of natural resources but also reduce the environmental impact during the product life cycle.

production process

During the production process, we take various measures to reduce energy consumption and waste generation. For example, we improve energy efficiency by optimizing production processes and equipment; use efficient wastewater treatment systems to reduce water pollution; and implement waste recycling programs to maximize the use of raw materials and reduce waste.

SDG support

As a durable and reusable product, non-woven bags directly reduce the use of single-use plastic products, which is closely related to the global sustainable development goal of reducing plastic pollution. By offering consumers this eco-friendly alternative, we encourage the masses to adopt a more sustainable lifestyle.

Introduction to Single Process Technology

Flow Rock Composite Technology

Versatility and Efficiency: This technology can provide versatile and efficient solutions for creating strong, durable structures and components.

Customization: The flow properties of composites before curing can allow for a high degree of customization in the shape and size of the final product for complex or unique design needs.

Durability and Sustainability: Enhanced material properties can result in a product or structure that is not only more durable, but potentially more sustainable if the materials used are recyclable or have a lower environmental impact.

The double-layer ten-color printing machine is a highly efficient printing device designed specifically to meet the needs of complex multi-color printing. It can print two independent layers, each layer supports up to five different colors, so that the whole machine can print up to ten colors. This model is particularly suitable for occasions with high requirements for printing quality, such as packaging materials, exquisite advertising materials, high-end books and periodicals, etc.

Main Features

High efficiency: The double-layer structure can perform two sets of different printing operations at the same time, greatly improving production efficiency.

High precision: Equipped with an advanced printing control system to ensure accurate overprinting of each color, clear output quality and bright colors.

Flexibility: Suitable for printing on a variety of materials, including paper, plastic, metal film, etc., providing more options for product packaging and advertising.

The use of fully automatic equipment for one-time molding production significantly improves the production speed and product quality of non-woven bags.

The main advantages of one-shot molding technology include:

Efficiency: The use of fully automatic equipment greatly reduces manual operation steps, thereby significantly improving production efficiency and capacity. This is especially important for companies that need to produce non-woven bags in large quantities.

Stability and environmental friendliness: The automated production process ensures consistent quality and size of each non-woven bag, reducing the possibility of human error and product defects. Material waste is reduced and production energy consumption is low.

Flexibility: Modern fully automatic equipment can be quickly adjusted to produce non-woven bags of different sizes, styles or printed patterns to meet the diverse needs of the market.

- Exhibit

Non-woven Handbag Customization Service – FAQ

Learn more about our environmental commitment and comprehensive solutions

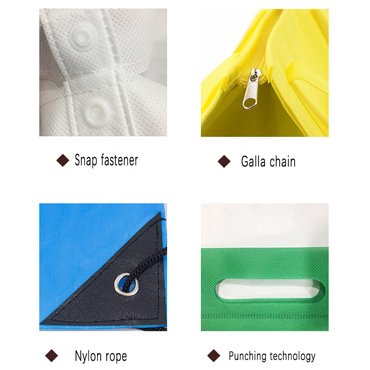

Of course. We offer complete customization including size, color, graphic design, and additional features (such as zippers, interior pockets, etc.) to meet your specific needs and brand image.

The production lead time depends on the complexity and quantity of the order. We adopt efficient production processes and logistics systems to ensure that delivery times are as short as possible while maintaining high quality. Please confirm the specific cycle with us when placing an order

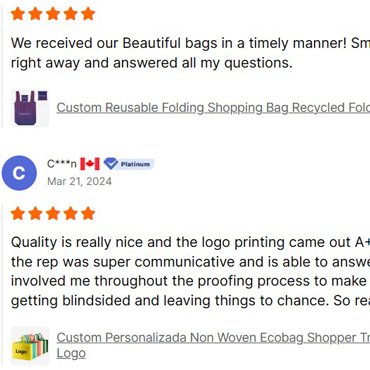

We implement a strict quality control system and conduct meticulous management and testing in every aspect from raw material procurement to production to ensure that each product reaches high quality standards. We are confident in the quality of our products and provide corresponding after-sales services.

Non-woven bags are suitable for a variety of occasions, including as shopping bags, promotional items, conference information packages, personal daily use, etc. They are practical and environmentally friendly, making them ideal for promoting your brand and demonstrating corporate social responsibility.

Yes, the materials used in our non-woven tote bags are not only environmentally friendly, but also recyclable. Some products use special degradable materials to further reduce the impact on the environment.