Professionalism and Quality

- Patterns and logos can be customized, using laser engraving and thermal transfer technology.

- Choose only high quality wool fibers

- Sewn with highly durable polyester and nylon thread. (The thickness of the sewing thread is usually 20 or 30 gauge to ensure durability)

- Common sewing needle sizes are 90/14 or 100/16 to ensure high quality sewing.

- Before large-scale production, small samples will be carried out to test the best combination of needles and threads.

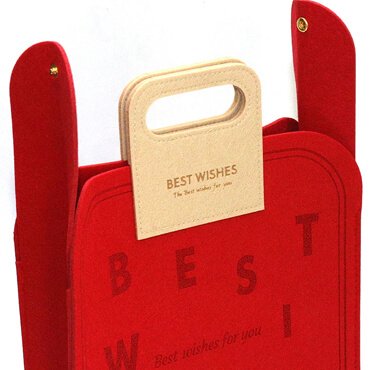

XINYUAN Felt Bag

We are now making every effort to expand the global market and sincerely invite agents from all over the world to join us and create a better future together.

Felt bags, with their stylish and practical features, have become a popular choice in the market. As a manufacturer with 17 years of experience, our felt bags not only pursue the perfect combination of fashion and practicality in design, but also strictly control material selection and craftsmanship to ensure that each product can meet your diverse needs. Whether used for everyday shopping, carrying office documents, or as personalized gifts, our felt bags deliver performance and style that exceed expectations.

Our advantage lies in the use of high-quality felt materials, combined with advanced production equipment and fine craftsmanship, each felt bag has both beauty and durability. As a source manufacturer, we can not only guarantee product quality, but also provide market-leading fast delivery services to meet the needs of large-volume orders. Our extensive product line offers a variety of sizes, colors and custom design options to suit different markets and the individual needs of our customers.

When you choose our felt bags, you not only get a stylish and practical product, but also enjoy our professional service and support as an industry leader. We are committed to providing every customer with high-quality products and a satisfactory shopping experience, so that you can be confident in every choice you make.

Customized Attachment Features

Ability to provide felt bags of different sizes according to customer needs or specific uses, whether it is a small cosmetic bag or a large-capacity shopping bag.

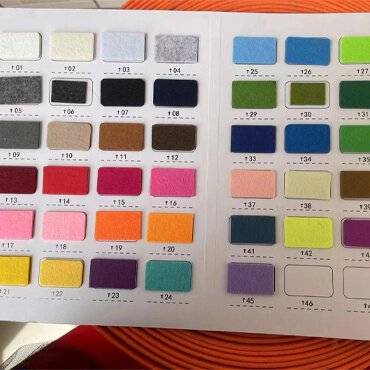

A variety of color options are available, even including specific color matching services, to match corporate brand identity or personal preference.

Use printing, embroidery or laser engraving technology to add unique patterns, logos or text to felt bags to provide personalized decoration services.

The exterior can be customized to add three-dimensional plush accessories

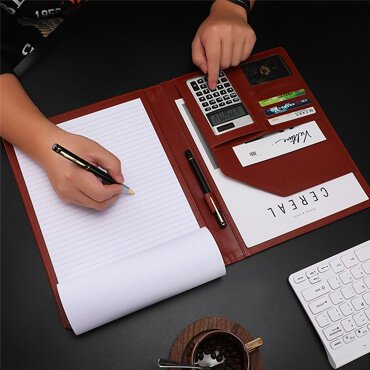

Add mobile phone bags, pencil bags, computer compartments or other small object compartments according to customer needs to enhance the practicality of the felt bag.

A variety of zipper and fastener options are available, including metal, plastic or magnetic fasteners to meet different design and functional needs.

To increase durability, add a reinforcement layer to the bottom of the felt bag, or use a bottom design of different materials.

Work with customers to jointly develop new product designs based on design concepts or sketches provided by them.

Quality Control System

Production Process Technology

Product Feature Box

Handmade Arts

Exquisite hand-sewing: Each felt bag is carefully hand-sewn by craftsmen, which not only ensures its extraordinary durability, but also demonstrates the craftsman’s pursuit of aesthetics and quality in every stitch and thread, making each felt bag The products exude unique craftsmanship and beauty.

The charm of unique decoration: Our felt bags incorporate the essence of traditional and modern design through fine embroidery, dazzling bead decoration and other handicraft techniques, giving each bag a unique artistic style, making it not only practical but also A masterpiece with ornamental value.

Carrier of cultural transmission: Choosing our felt bags is not only choosing a high-quality and multi-functional product, but also choosing a cultural and aesthetic inheritance. They represent a unique attitude towards life and elegant taste, making every carry a cultural display and an expression of personality.

Material Properties

Environmentally Friendly Choice: Felt is made from natural renewable resources and is easy to degrade naturally. It reflects respect and protection for the earth and is an ideal choice for those who pursue a sustainable lifestyle.

Durable: The dense fiber structure of felt gives it excellent wear resistance and can maintain its original condition even under frequent use, greatly extending the service life of the product.

Soft touch: The natural soft touch of felt ensures comfort during use. At the same time, its cushioning properties can effectively protect the contents of the bag from external impacts and scratches.

Thermal Insulation: The unique thermal insulation properties of felt make it an ideal material for protecting temperature-sensitive items such as food and certain electronic equipment, and performs well in both cold chain and heatstroke prevention.

Dustproof and waterproof: Although felt is not completely waterproof, it can prevent the intrusion of moisture and dust to a certain extent, providing an extra layer of protective barrier for the contents of the bag.

Design Aesthetics

Stylish appearance design: Our felt bag design team is committed to integrating modern aesthetics and practical functions to create a simple yet elegant appearance, ensuring that each felt bag can become an extension of the carrier’s style and suitable for various business or leisure occasions.

Rich color options: From deep classic tones to bright vibrant colors, we offer a wide range of color options, allowing every consumer to find a felt bag that reflects their personality and style, easily matching different outfits and moods.

Personalized customization services: In order to meet unique personal or corporate needs, we provide customized services in size, pattern and text. Through high-precision printing technology, each felt bag exudes a unique charm and becomes a symbol of brand communication and personal expression. tool.

Fine craftsmanship and details: Each felt bag is carefully crafted, paying attention to the quality of even stitching, smooth edges and attached small accessories, demonstrating our pursuit and commitment to excellent craftsmanship, ensuring that every product is a work of art.

Professional Collocation and Selection

Application of laser engraving on felt bags

Laser engraving uses a high-energy laser beam to precisely remove surface material to form fine patterns or text. Its features on felt bags are as follows:

High precision: can achieve delicate and exquisite designs with clear edges.

Non-contact processing: no mechanical pressure, does not affect the original texture and shape of the felt.

Durability: the engraved pattern does not fade, does not wear, and is long-lasting and durable.

Color restrictions: only the surface material is removed to show the design, and the color is limited to the color of the felt itself.

Application of thermal transfer on felt bags

Thermal transfer transfers the pattern from transfer paper to felt through high temperature, which is suitable for adding colorful patterns or text to felt bags. Its characteristics are as follows:

Rich colors: full-color printing is achieved, with bright colors, suitable for complex pattern design.

Wide application: almost any pattern can be transferred, with strong adaptability.

Change in feel: large-area transfer may slightly change the feel of the felt surface.

Durability: Modern thermal transfer has improved durability, but compared with laser engraving, the transferred pattern may not be as durable as engraving under frequent friction or washing

We often use polyester and nylon threads:

Polyester thread: high strength, wear resistance, good color fastness, suitable for durable felt bags.

Nylon thread: suitable for seams with high strength and elasticity requirements, but sensitive to high temperatures.

Cotton thread: heat-resistant and soft, suitable for projects pursuing natural textures, but with lower strength and wear resistance.

Thread size (Tex Size): Tex 40 to Tex 70 is recommended to ensure a balance between strength and beauty.

Matching needle size: thick thread needs to be matched with a large needle to ensure smooth sewing.

- Evaluate

Professional Felt Bag Supplier – FAQ

Learn more about our products, services and cooperation advantages to help your business grow.

Our monthly production capacity varies according to product complexity, and the average monthly production capacity can reach X million pieces of felt bags. For large batch orders, we are able to meet customer needs by adjusting production lines and working overtime production.

For large quantity orders, we can provide competitive wholesale prices. The specific discount rate is determined based on the order quantity and product specifications. We welcome customers to consult and discuss this in detail.

Our minimum order quantity depends on the specific product, generally it is XXX pieces. For customized products, MOQ may vary, please contact us for specific information.

We provide a variety of logistics solutions, including sea freight, air freight and express delivery, to meet different time and cost needs. We can also provide customized logistics services based on customers’ specific needs.

We provide sample service to ensure the product meets your needs. The cost of the sample depends on the complexity of the sample. After the order is confirmed, the sample fee can be deducted from part or all of the order amount.