Material Information

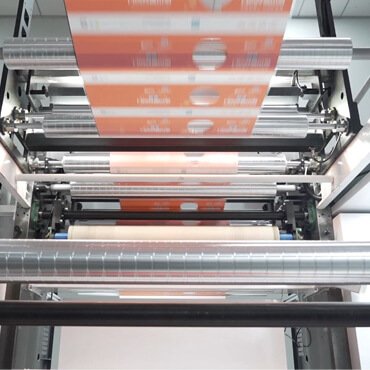

We use a multi-layer co-extrusion process to make films made of PA/PE.

- Combining advantages: Polyamide (PA) provides strength and gas isolation, polyethylene (PE) is responsible for excellent sealing.

- Food safety: Comply with international food safety standards, release harmless substances, and be directly used in food packaging.

- Environmentally friendly: PE materials are recyclable, reducing environmental impact and supporting sustainable development goals.

- Protective performance: high physical strength, resistant to tearing and puncture, protecting product safety during transportation and storage.

- Extended storage: effectively blocks oxygen and other gases, extends the shelf life of food, and keeps products fresh.

Freshness Preservation Innovation, Food Safety Choice

Vacuum bags are an efficient packaging solution that use the method of extracting air from the bag and sealing it tightly to significantly delay the oxidation and spoilage process of the product, effectively maintaining the long-term freshness and safety of food and other sensitive products. These bags are usually composed of multiple layers of high-barrier materials, which can effectively prevent the intrusion of moisture, dust and microorganisms, providing comprehensive protection for products. Vacuum bags are widely used. They are not only used in the food industry for long-term preservation of meat, seafood, vegetables, etc. to maintain their nutrition and taste. They are also used in the medical industry to protect medical equipment to maintain sterility, and in the electronics industry to prevent moisture. Gas and dust can damage sensitive components. In addition, it is also used for the preservation of culture and artwork to prevent oxidation and fading. The versatility of vacuum bags makes them ideal for protecting and extending the life of products in a variety of industries.

Customized Services

We offer a comprehensive customization service to ensure our vacuum bags perfectly fit your specific needs

- Customized sizes: Whether you need small bags for sample packaging or large bags for bulk product preservation, we offer a variety of size options to ensure you meet your specific needs.

- Thickness selection: Depending on the characteristics and protection needs of your product, you can choose different bag thicknesses. From ultra-thin to enhanced protection, we can provide the most suitable solution.

- Print customization: Provide high-quality customized printing services. Whether it is a simple brand logo or complex product information and design patterns, our printing technology can ensure clear and lasting visual effects.

- Special functions: including but not limited to easy tearing, re-sealing, hanging hole design, etc., to increase the user-friendliness and convenience of the product.

Production Process (4)

After-Sales Service Team (5)

Safe, Reliable and Efficient - Your Best Food Companion

Vacuum Packaging Solutions FAQs

Learn more about our innovation, customization and customer commitments

Vacuum bags slow down the oxidation and bacterial growth of food by extracting the air inside the package, thereby extending the shelf life of food. In general, vacuum packaging can extend the shelf life of food by 3 to 5 times, depending on the type of food and storage conditions.

Our vacuum bags are suitable for a wide range of food types, including but not limited to meat, seafood, fruits and vegetables, dried fruits, cheese, and various prepared foods. Specially designed vacuum bags are also suitable for liquid or juice-laden food packaging.

Yes, a vacuum sealer is required to extract the air from the bag and seal the bag mouth. We offer different models of vacuum sealers for both home and commercial use, and are happy to recommend the right equipment for your needs.

Absolutely. All our vacuum bags are produced using food-grade materials, do not contain BPA (bisphenol A) and other harmful substances, and fully comply with international food safety standards.

We offer specific types of vacuum bags that are specially treated to be safe for microwave use. Please make sure to read the product instructions before use and choose a product suitable for microwave heating.

Yes, we provide a full range of customization services from size, thickness to printing customization. Whether it’s branding, instructions, or a special design, our team can handle your customization needs.

When choosing a suitable vacuum bag, you need to consider the material, size of the bag, and the type of food that needs to be packaged. Our sales and technical teams are happy to assist you in selecting the product that best suits your needs.