Material Information

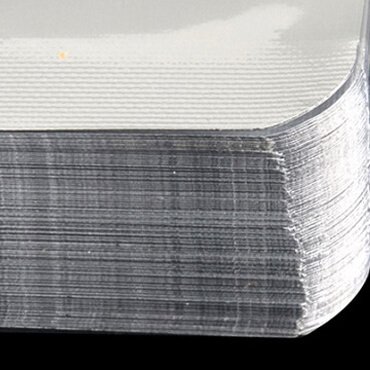

- PET (polyethylene terephthalate): PET is a material with good heat resistance and can withstand high temperatures during continuous cooking. It has good transparency and rigidity, making it an ideal choice for outer layers. PET also has good chemical stability and will not react with food, ensuring food safety.

- Nylon: Nylon is known for its excellent mechanical strength and heat resistance, making it an ideal choice for improving the overall strength of retort bags. The nylon layer provides additional protection during the cooking process, preventing the bag from cracking or deforming.

- Aluminum Foil: The aluminum foil layer is a key material used to provide excellent barrier properties. It can effectively prevent the penetration of oxygen, water vapor and other gases, maintain the freshness of food and extend the shelf life. Aluminum foil also has reflective properties that block light, further protecting food from the effects of photo-oxidation.

- PE (polyethylene): PE is usually used as the inner layer material and is widely used because of its excellent sealing performance and safety. It remains stable at high temperatures, ensuring reliable sealing at the end of the cooking process.

XINYUAN Retort Bags

Our retort bags are designed to meet the most stringent food processing standards, especially during high-temperature retorts. These bags can withstand temperatures up to 135°C (275°F) and remain in continuous high-temperature cooking without cracking or leaking, ensuring the safety and integrity of food throughout processing, storage, and transportation.

Our retort bags feature advanced multi-layer material technology, with each layer carefully selected to provide optimal thermal stability and physical strength. These materials can withstand not only the high temperatures of cooking, but also the low temperatures experienced during freezing and refrigeration, making them ideal packaging options for a variety of food processing environments.

The technology has a wide range of applications and is suitable for a variety of food types, including but not limited to meat, seafood, convenience foods, pet food and vegetables. Its excellent high temperature resistance ensures that the taste, nutrition and color of food can be retained during the cooking process, while also greatly reducing the risk of food contamination during the production process.

Choosing our retort bags means choosing an efficient, safe and economical food packaging solution. Whether your need is to increase the shelf life of your products, maintain the original flavor of your food, or simplify the processing process, our high temperature resistant retort bags can meet your needs and help your products stand out in the market.

Special Craftsmanship and Technology

- Solvent-free composite technology: This environmentally friendly technology reduces the use of harmful solvents and improves product safety and environmental protection.

- Lamination technology: Through high-precision lamination process, each layer of materials is ensured to be perfectly combined, enhancing the overall performance of the retort bag.

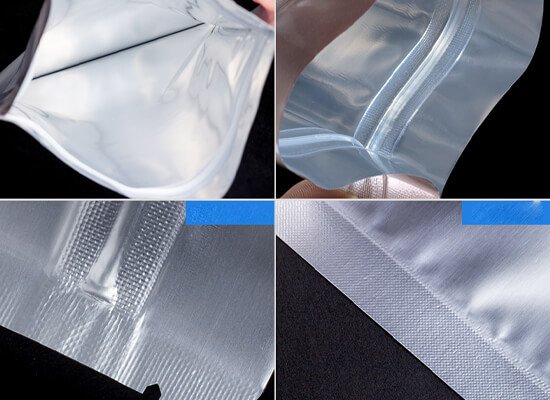

Sealing and Leak-Proof Design (4)

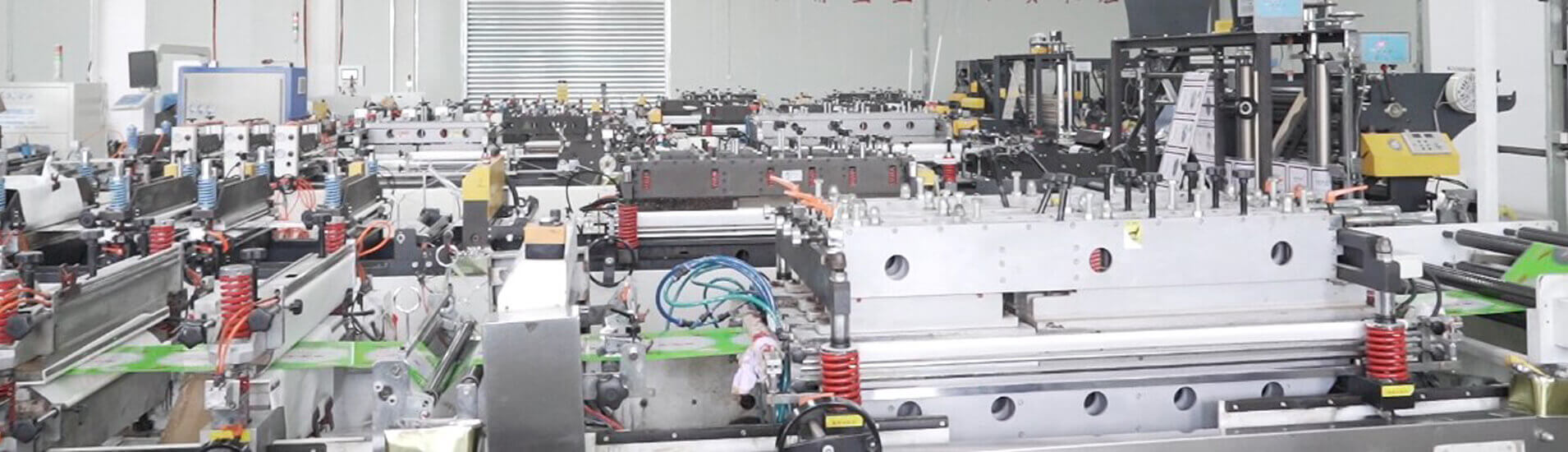

Manufacturing (6)

Choices and Features (Additional Features) (3)

Custom Packaging Solutions to Meet All Your Food Safety Needs

- Buyer Feedback

Upgrade Your Product Packaging – Choose Our Retort Bags

Enjoy customized solutions and comprehensive professional after-sales support

Our retort bags can withstand temperatures up to 135°C (275°F) and are suitable for all high-temperature retort processes to ensure food safety and quality.

Yes, we offer comprehensive customization services including size, shape, material selection, printing design, etc. to meet your specific needs and brand image.

We use advanced sealing technology and strict quality control processes, including seal strength testing and leakage testing, to ensure the sealing and safety of each bag.

Yes, all our retort bag materials comply with international food safety standards to ensure the safety and reliability of the products.

You only need to submit an inquiry through our website or contact our sales team, we will discuss your specific needs with you, provide a customized plan and quotation, start production and arrange delivery after confirmation.