Various Scenarios And Industries, Brief Introduction

- Cosmetics: Used to package various cosmetics, such as lipstick, eye shadow, liquid foundation, etc., to enhance the fashion and high-end feel of the product.

- Food: Suitable for packaging healthy snacks, candies, dried fruits and other foods to increase product appeal and enhance brand image.

- Clothing: used for packaging fashion accessories, small clothing items, such as socks, handkerchiefs, jewelry, etc., to reflect the brand’s unique style.

- Electronic products: Suitable for packaging small electronic products and accessories, such as mobile phone cases, headphones, data cables, etc., which are both beautiful and protective.

- Stationery: Used to package various stationery supplies, such as notebooks, stationery sets, stickers, etc., to increase the fun and appeal of the product.

High-Quality Holographic Packaging Bag Manufacturer - Professional Customization, Quality Service

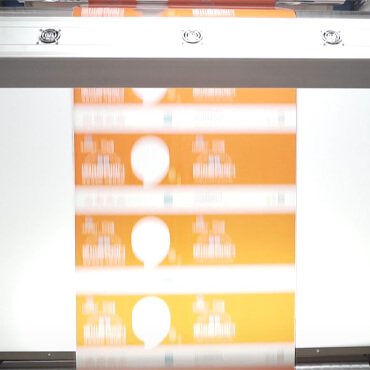

Our production factory is equipped with state-of-the-art holographic printing equipment and automated production lines, ensuring that each holographic bag has excellent visual effects and high-quality performance. We use high-resolution holographic technology and environmentally friendly material processing technology to produce holographic bags that are not only beautiful and durable, but also comply with international environmental standards. The factory has strong production capacity, with an average daily production capacity of hundreds of thousands, and can flexibly respond to large-scale order demands. Our professional team has rich experience and efficient service awareness, and is committed to providing customers with customized solutions and rapid response, ensuring that every order can be delivered on time, and providing customers with all-round support and quality services. When you choose us, you will get high-quality products and professional cooperation experience, allowing you to stand out in the market competition.

Product Material Characteristics

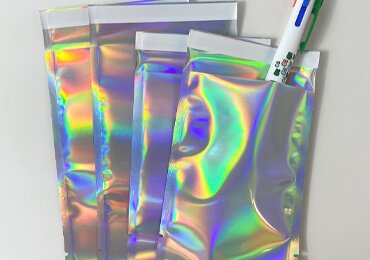

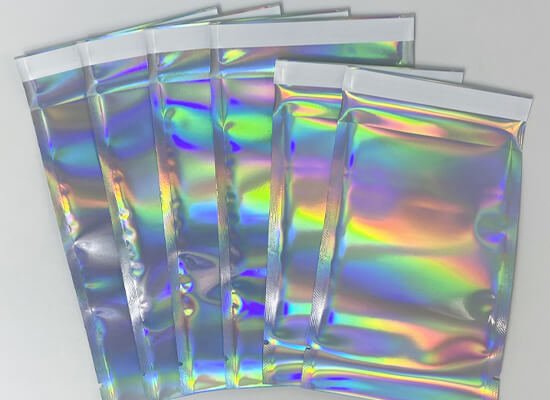

- High-quality holographic effect: Using advanced holographic technology, the surface of the bag presents a colorful iridescent effect, which is highly visual impact and eye-catching.

- Durability: Using high-strength materials, it has excellent durability, is not easy to break, and can maintain good condition for a long time.

- Waterproof: The holographic bag has excellent waterproof performance, which can effectively protect the items inside the bag and avoid damage due to moisture.

- Environmentally friendly materials: Made of environmentally friendly materials, in line with international environmental standards, it is both safe and environmentally friendly.

Quick Customization Process (6)

Serve (4)

Recruiting Agents to Explore New Markets for Holographic Packaging

- Feedback and Evaluation

Holographic Bag FAQ

Answer your questions and help you better understand our holographic bag products and services

Standard production time is 2-4 weeks, depending on order quantity and customization requirements. Delivery time varies depending on logistics method.

Our holographic bags mainly use PET and PVC materials, which have high transparency, durability and environmental protection properties.

Yes, our holographic bags are made of food-grade materials, comply with international food safety standards, and can be used for various food packaging.

Yes, we can provide samples for your evaluation, sample production usually takes 1-2 weeks.

You can contact us by phone, email or online consultation, or click on the right to initiate an inquiry. Our professional team will serve you wholeheartedly.