Leaking biohazard waste creates health hazards. Damaged waste also causes heavy fines. Protect people and budgets with proper packaging steps.

Use UN-certified packaging matching your waste class. Train staff on IATA/DOT rules. Keep documents updated and labels visible. These steps prevent leaks and avoid penalties.

Following rules is hard but essential. These answers help you ship legally.

What are the IATA packaging requirements for dangerous goods?

Wrong packaging causes carrier rejection. Fines follow instantly. Understand critical standards today.

Packaging must pass UN performance tests for your hazard class. Outer packaging needs markings, hazard labels, and absorbent material. Shipping papers must list emergency contacts accurately.

Core Packaging Standards Explained

IATA rules change often. Focus on these essentials:

-

Container Selection

Use triple-layered packaging: leakproof primary container + absorbent material + rigid outer shell. This prevents spills during handling. -

Labeling Rules

Apply diamond-shaped Class 6 hazard labels visibly. Include full shipper/consignee details and “Biological Substance, Category B” text.

| Requirement | Details |

|---|---|

| UN Certification Mark | Must show UN code (e.g., UN2814) and passed test type (6.2) |

| Absorbent Capacity | Include material soaking 2x liquid volume inside primary container |

| Documentation | Attach Shipper’s Declaration with 24/7 emergency contact phone number |

Always check current IATA Dangerous Goods Regulations. As a manufacturer with 30+ years experience, our XINYUAN team updates packaging specs monthly. This avoids fines for clients.

How do you transport biohazardous waste safely?

Transport errors risk contamination. Exposure incidents stop operations. Secure every transfer correctly.

Place waste in UN-rated bags labeled “Biohazard”. Use rigid, spill-proof outer containers. Train handlers in OSHA bloodborne pathogen protocols. Never overfill bags.

Critical Transport Stages

Manage these phases separately:

-

Pre-Transport Prep

Double-bag waste at generation site. Add absorbent pads between layers. Seal bags with zip-ties. Write collection date on outer bag. -

Vehicle Requirements

Use leakproof secondary containment in vehicles. Maintain 40°F-90°F temperature range. Separate biohazard waste from clean supplies. -

Tracking Systems

Use chain-of-custody forms with signatures at transfer points. Keep manifests for 3 years minimum.

I help brands avoid DOT fines. With automatic production lines and free samples, we create custom bags. These handle Category B substances securely.

What are category A substances?

Misidentifying Category A brings million-dollar fines. Health workers face severe infection risks. Recognize dangerous pathogens instantly.

Category A includes life-threatening substances like Ebola or Anthrax. They cause permanent disability or death. These require UN2814 packaging and infectious substance labels.

Handling Category A Materials

Treat all suspected samples as Category A until proven otherwise:

-

Classification Triggers

Category A applies to substances known to transmit disease in humans. High-consequence pathogens automatically qualify. -

Emergency Protocols

Immediately isolate leaks. Contact CDC or local health department. Wear NIOSH-approved respirators and double gloves.

| Difference | Category A | Category B |

|---|---|---|

| Packaging Standard | UN2814/UN2900 compliant | UN3373 compliant |

| Label Requirement | "Infectious Substance" diamond | "Biological Substance" diamond |

| Shipping Declaration | Mandatory special permissions | Standard declaration |

As an exporter, we produce DOT-compliant UN2814 bags. Our automated lines run 24/7. This supports hospitals during outbreaks. Ask for free samples to test durability.

When packing any Biological substance category B, the following is always true?

Cutting corners with Category B causes leaks. Contamination lawsuits destroy profits. Apply non-negotiable rules every time.

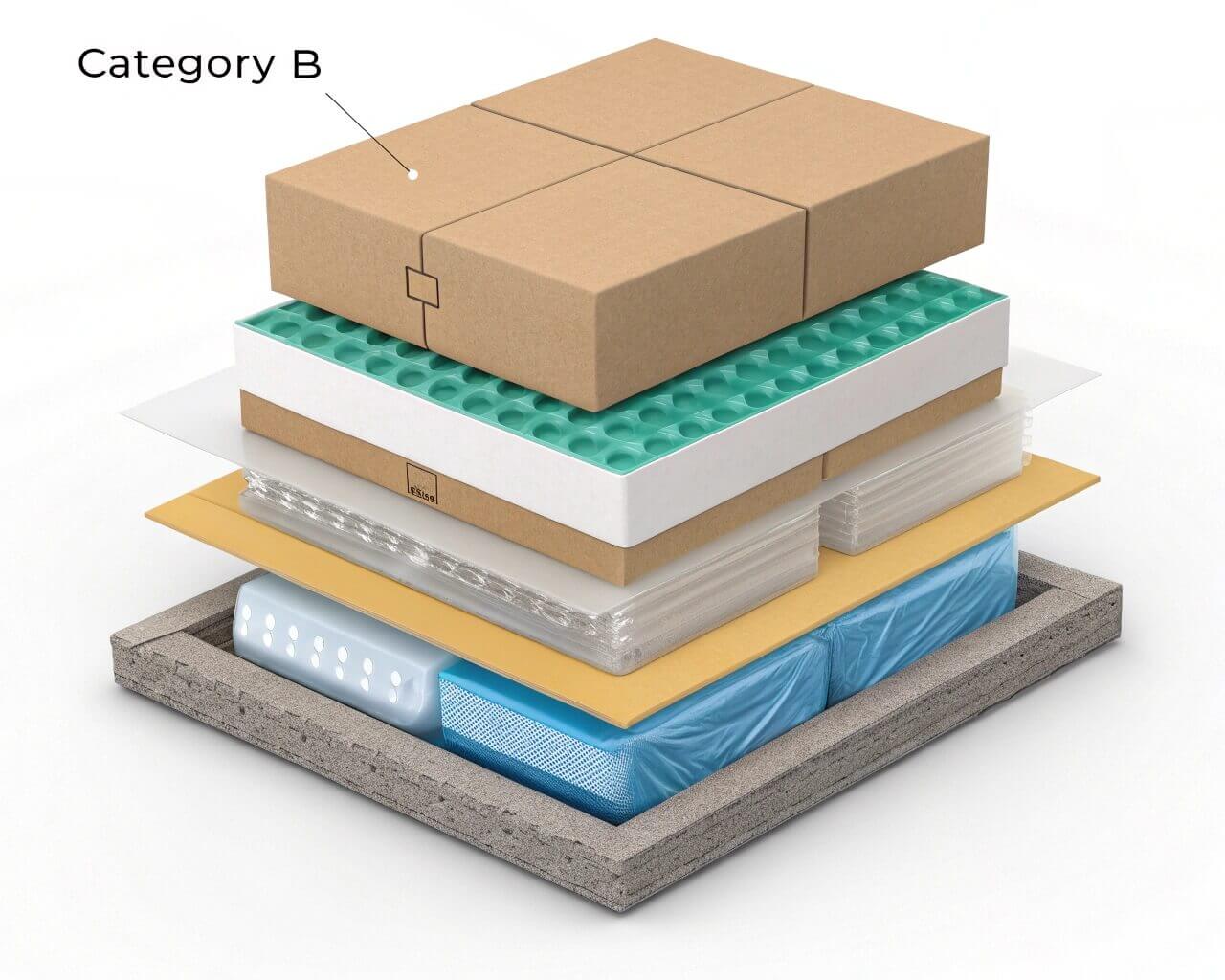

Always use triple-packaging: primary receptacle + leakproof outer bag + rigid box. Always mark "UN3373" on outer packaging. Always include absorbent material for liquids.

Universal Category B Rules

These standards never change:

-

Primary Containers

Use unbreakable vials or tubes. Fill only 75% capacity. Secure screw caps with sealing tape. -

Absorbent Requirements

Place cellulose pads between primary and secondary layers. These must hold 300% of liquid volume. -

Testing Validation

Packaging must pass drop tests (1.8m height) and pressure tests (95 kPa for 30 mins). Ask manufacturers for test certificates.

Our factory runs 50+ machines. We create UN3373 bags passing all tests. Free typesetting service ensures your DOT labels print correctly. Bulk orders include waived sampling fees.

Conclusion

Use tested packaging and trained procedures. This ensures safe biohazard transport. Avoid fines with continuous compliance.