Packaging Bag Step by Step Production Process

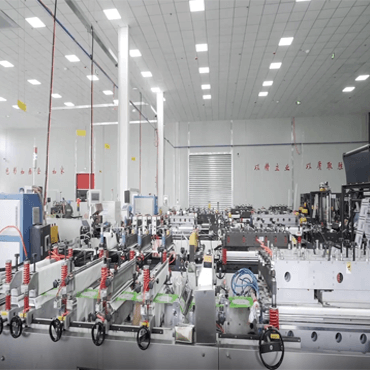

We have industry-leading equipment, more than 17 years of R&D and production experience, and highly strict quality control, with the ability to handle large and multi-batch orders.

First of all, we need to determine the printing pattern and content, and use the pattern designed by the designer or the pattern sent to us by the customer.

The second step is to select production materials after confirming the printing content.

Compound different materials into a multi-layer structure through adhesives or heat pressing to improve the strength and functionality of the packaging bag.

The composite materials are cured to fully cure the adhesive and ensure strong bonding between the layers.

The design pattern is printed on the surface of the composite material, usually using the gravure printing process to ensure clear printing and bright colors.

Cut the large roll of composite material into small pieces according to the size requirements of the packaging bag.

The cut materials are made into the finished shape of packaging bags through processes such as heat sealing and folding.

Conduct quality inspection on finished packaging bags to ensure that the sealing, durability, etc. meet the requirements.